There is a lot of excitement in the solar industry about PERC technology. If you’ve heard the term, but aren’t completely sure what it means, you aren’t alone.

PERC stands for Passivated Emitter and Rear Cell technology. Depending on where you look, you may also see it referenced as Passive Emitter and Rear Contact.

Although the technology itself has existed since the mid-1980s, it only started to be utilized at the research level more recently. It took years for the general solar industry to reach the same efficiencies.

Now that advanced technology is available, knowing more about it can help you decide if it’s a good fit for your solar needs. In this article, we’ll explain everything you need to know about PERC technology as it relates to solar panels.

What is PERC in Solar?

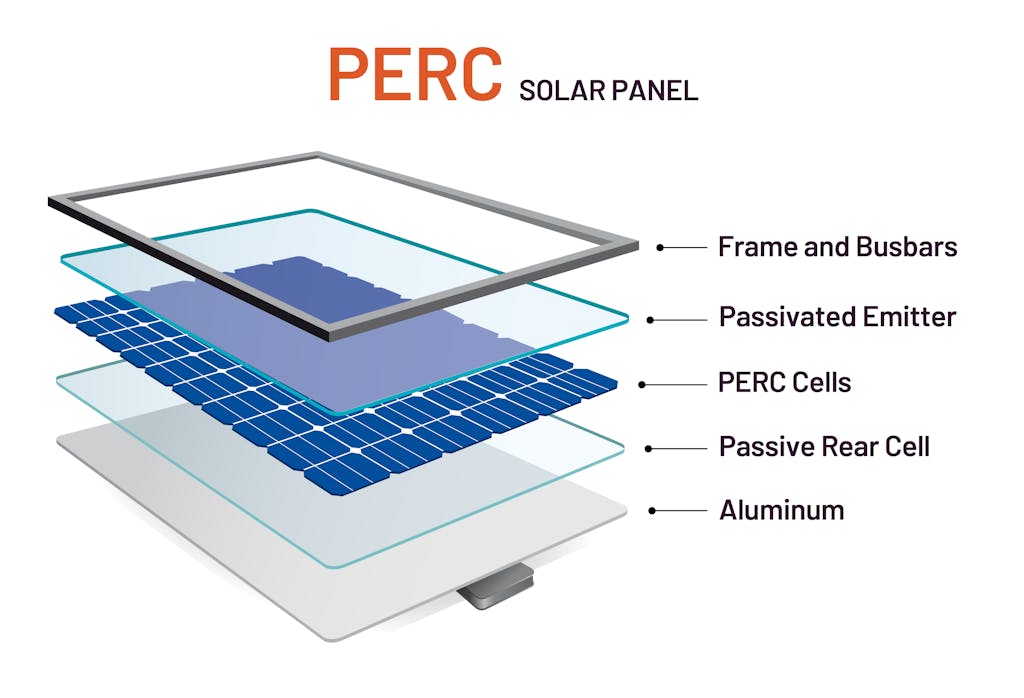

A scientist in Australia named Martin Green and his team at the University of New South Wales developed PERC technology in the 1980s. This technology takes a traditional solar cell and adds an additional layer to the backside of the cell. This extra layer is termed the passivation layer.So, how does a PERC solar cell work? The passivation layer acts as a mirror and reflects light that passes through the panel the first time. This gives the light a second chance to be absorbed by the solar cell and results in greater absorption of solar radiation.

For years manufacturers of solar cells directed all of their attention to the front side of a solar cell. PERC technology allows the backside of the solar cell to play an active role.

What Are the Benefits of PERC Solar Cells?

PERC solar cells are beneficial for a number of reasons. The main benefit is they achieve higher efficiency ratings than traditional solar cells. PERC technology enables the solar cell to absorb more light and this effectively boosts energy production. Although additional steps are needed in the manufacturing process, the efficiency gain makes it well worth it.

Another benefit of PERC solar cells is they grant you more flexibility. PERC technology works well in low-light and high temperatures. By having a greater energy density per square foot than traditional solar cells, you can utilize PERC solar cells to achieve your desired output with fewer panels. These attributes make solar possible in spaces or locations where it might otherwise seem a poor fit.

The ability to achieve the same output with fewer panels translates to cost savings. Being able to achieve your energy goals for less is always desirable. For some projects, this cost savings can mean the difference between going solar and just dreaming about it.

How Are PERC Solar Cells Different?

At first glance, you may not notice any obvious differences between a PERC solar cell and a typical photovoltaic solar cell. The construction of both cell types is similar and they both use incoming solar radiation to generate a flow of electrons.

The main difference between PERC solar cells and monocrystalline photovoltaic cells is the additional passivation layer on the backside of the solar cell. This layer is what increases the panel’s energy generation by boosting efficiency.

Wondering how does a PERC solar cell work to improve efficiency? Here are 3 ways the back surface passivation layer results in increased efficiency:

1. Reflects light back through solar cell

The back surface passivation layer acts as a mirror and reflects light that passes through the solar cell unabsorbed the first time. This gives the solar cell a second chance to absorb the light.

This second absorption attempt means more solar radiation will be directed to the cell. The very same cell is able to produce more energy which translates to greater efficiency.

2. Heat absorption is reduced

Another benefit of the passivation layer on PERC solar cells is that it reflects certain wavelengths of light. Solar cell silicon wafers cannot absorb light with wavelengths greater than 1180 nanometers.

This means that in a traditional cell, the higher-wavelength light waves get absorbed by the rear back layer of the solar cell. Absorption of the light here causes increased heat and as a byproduct reduced efficiency.

By contrast, a PERC solar cell’s back surface passivation layer is designed to reflect these higher-wavelength light waves so that they are not absorbed by the solar cell. In this way, heat energy in the solar cell is reduced and as a result, efficiency is increased.

3. Electron recombination is reduced

A third way the back surface passivation layer increases efficiency is that it reduces “electron recombination”. Electrons have a tendency to recombine and when they do, it blocks the free flow of electrons throughout the solar cell lowering efficiency. The added passivation layer in a PERC solar cell reduces electron recombination and this reduction boosts efficiency.

What is Mono PERC Solar?

Mono PERC solar is the most efficient solar available. When comparing monocrystalline vs. polycrystalline solar panels, monocrystalline panels have a higher efficiency rating. By adding PERC technology to this already superior solar panel, it’s possible to generate 6 to 12 percent more energy with mono PERC solar than with conventional solar panels.

One thing to note is that mono PERC solar panels are not the same as bifacial solar panels. Bifacial panels are made with dual-sided solar cells that are capable of absorbing sunlight on both sides of the panels.

How Are PERC Solar Cells Made?

Manufacturers make PERC solar cells by adding two additional steps to their solar cell process. Both of these steps occur on the back surface field (BSF) of the solar cell.

The first step is to apply the rear surface passivation film which is a dielectric passive layer. Once that has been applied, the rear surface passivation film is etched with chemicals or lasers to open tiny pockets in the layer. These pockets are what allow the panel to absorb more light.

The same equipment that is used for traditional solar cells can be employed for PERC solar cell production meaning manufacturing lines don’t need to invest in new equipment. This allows manufacturers to produce a superior product without any significant increase in manufacturing costs.

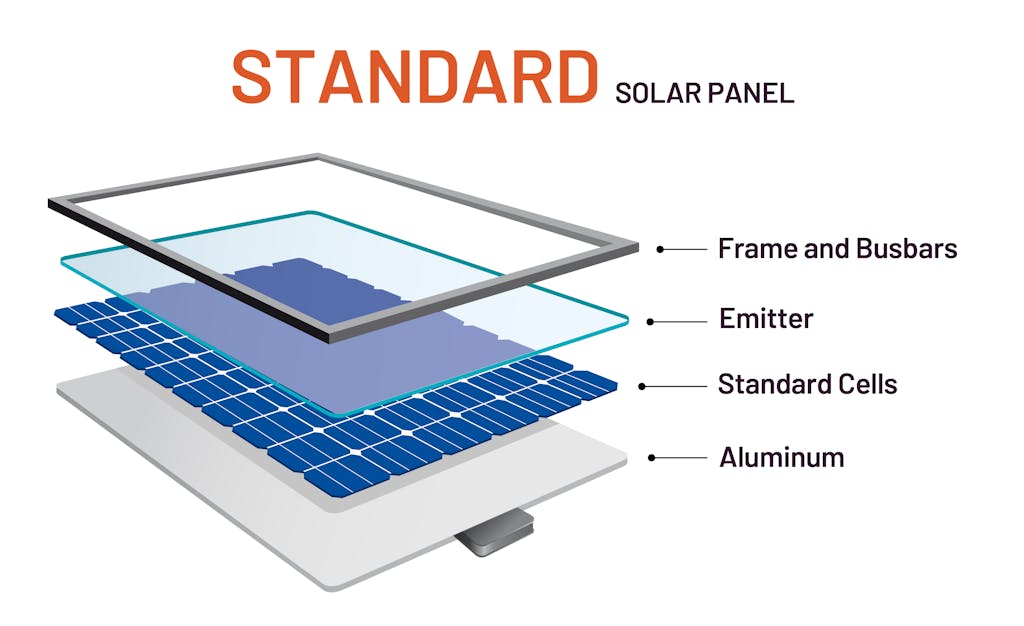

A conventional, or traditional solar cell consists of the following from front to rear:

- Screen-printed Silver paste front contact

- Anti-Reflective Coating (ARC)

- Silicon wafers that form the P-N junction

- Aluminum Back Surface Field (AI-BSF)

- Screen-printed Aluminum paste layer

From front to rear, a PERC solar cell is comprised of:

- Screen-printed Silver paste front contact

- Anti-Reflective Coating (ARC)

- Silicon wafers that form the P-N junction

- Local Aluminum Back Surface Field (Al-BSF)

- Dielectric passivation layer

- SiNx Capping Layer

- Screen-printed Aluminum paste layer

Solar technology continues to evolve and improve each year. PERC technology is a great example of how a small change to the existing design of solar panels makes a big impact.

N-Type vs. P-Type Solar Cells

Another advancement in solar panel cell technology has been the introduction of N-Type solar cells. Compared to traditional P-Type technology, solar panels with newer N-Type cells degrade less over the life of the panel.

What are N-Type Solar Cells?

N-type cells are doped with phosphorus, which has one more electron than silicon, making the cell negatively charged.

N-type cells are immune to boron-oxygen defects, and as a result, they are not affected by light-induced degradation (LID). As you might expect, these are positioned as a premium option because they degrade less over the life of the panel.

What are P-Type Solar Cells?

P-type cells are usually built with a silicon wafer doped with boron. Since boron has one less electron than silicon, it produces a positively charged cell.

P-type cells are affected by light-induced degradation, which causes an initial drop in output due to light exposure. This has historically been the most common treatment method for solar cells.

Questions?

You’ve taken the time and learned about PERC technology and what it means for solar. Feel free to reach out to us with any questions you may have. We’ll be happy to go over what technology seems like the right fit for your solar project.